Newb Brake Job, Day 1

So I finally got all of the parts and decided to have at it. The following are some notes from Day 1. I thought I’d post these notes while it’s still fresh in my mind so it might help some other newbs.

As a recap, I’m replacing everything but the calipers (though some people have recommended that I just get new ones … and I might yet).

Here’s the list:

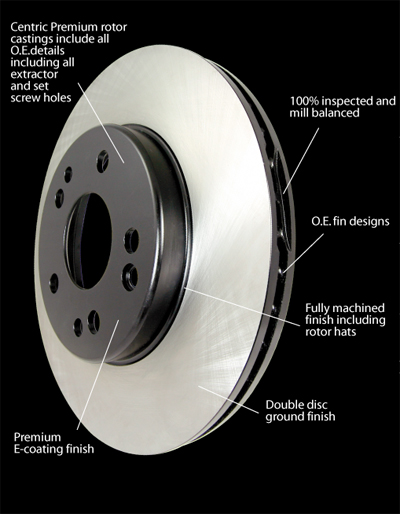

New Rotors: Front and rear Centric rotors (blanks, slightly upgraded)

New Pads: CarboTech 1521 Street Pads

New Hoses: Goodridge Stainless Steel (front and back)

New Fluid: ATE Super Blue

I’ll comment on the workflow, point by point…

- Car on jackstands, remove wheels

This is pretty basic really though I found myself annoyed because I couldn’t find my jack and jackstands after my most recent move. I picked up some cheap Chinese floor jack + 2 jackstand deal at Advanced for $40. I wouldn’t say it was a total waste of money, but if you want to jack up the car from the front or rear jack point to place the jack stands I wouldn’t do it again.

The damn floor jack couldn’t jack up the Teg high enough from either the front or rear jack points to place its own jack stands. After that I read an article on floor jacks on the net. Turns out almost all floor jacks are now made cheaply in China and aren’t meant to last more than 10 up/down cycles before their seals leak.

The only jack still made in the US runs about $600. You can get some good Japanese jacks for a little over half that from Norco. Norco also sells a version of their jack made in China, but strictly according to their design and seals. If you look around you can find it for about $215.

Anyway, since I didn’t want to wait another week for a good jack I used the floor jack to jack the car on its corners right near the jack points. I don’t like doing that because I often see that technique crumples the steel next to the jack point. Anyway, I was careful and everything was okay.

- Drain brake fluid as best you can

There are a lot of different ways you can do this, but the following worked suprisingly well for me…

(drain master cylinder)

– get one of those water bottles made for cyclists that has a pop open valve at the top

– buy some clear vinyl tubing (3/8" at Home Depot I think) to drain the fluid with

– drill a hole in the top of the bottle and feed the tubing all the way to the bottom

– take off the master cylinder cap

– open the bottle valve, squeeze it all the way, close the valve and put the end of the tubing into the master cylinder reservoir.

– release the bottle and it will suck a large amount of fluid from the master cylinder

(drain lines)

– after removing the wheels, setup shop towels down under each wheel while draining. Place a drain pan under each wheel while working there.

– remove the bleed cap and crack open the bleed valve just a little. these can be stuck tight so I always use a socket wrench. don’t open them all the way or you’ll be spilling fluid on the floor

– attach the bleed tube and bottle and open the bottle valve

– squeeze the bottle, close the bottle valve and set it down

– using the box wrench open up the bleed valve until you get maximum fluid drain

– repeat for all wheels. you’ll get most of it out.

- Remove brake hoses, calipers, and rotors (will be easiest in that order)

(brake hose removal)

Here is what I did with only a couple issues…

– if your wheel well is really dirty, clean it up a bit to make it easier.

– if you have any corrosion on the bolts/parts put some break free or PB catalyzer on the hose/line interface, hose clip, retainer bolts and banjo bolt (where it connects to the caliper).

– while you’re at it, put some more on the caliper bolts and caliper mount bolts

– give it a while to sink in

– start at the top of the brake hose at the interface where it mates with the steel brake line

– use a 10mm flare wrench to open the joint

– unscrew it by hand

– there’s a steel clip at that interface that needs to be removed and it can be a pain. depending on the level of crud, corrosion and the phase of the moon a needle nose pliers can sometimes be used to remove it. when you grab it, slide it back and forth to break it free of the old crap. that seems to help.

– if you get a sticky retainer clip, try using one of the combination needle nose/vice grip things which will help with yanking it out. apparently there are special needle nose pliers which are made especially for pulling clips like that out towards you. if you have one, you’re in luck.

– the rest of the hose is easy to disconnect, just loosen the bolts with a socket wrench. you might want to write down the exact location of the mounting clips.

– the last bolt, the banjo bolt is connected directly to the caliper. crack it open with a socket and back it out by hand. be careful. you’ll notice as it comes out it starts leaking brake fluid even though you just drained the fluid. this is one of the areas where the remaining brake fluid collects so make sure you have your drip pan underneath while doing it. when the banjo bolt comes free you’ll probably get several ounces of brake fluid pouring out.

(caliper removal)

– You’ll have two sets of caliper bolts to remove. Both sets are on the wheel well side of the caliper. One set is on the caliper itself and the second is on the caliper mount. The two bolts on the caliper itself are on the forward part of the caliper, one high and one low. They aren’t usually too hard to remove since you’ve already applied PB Catalyst.

The second set are on the caliper mount – the part the caliper rests on and where the pads join the rotor. They are just rearward of the caliper bolts and can really be a pain to remove. If you have a small pneumatic impact wrench they might come off fine, otherwise I find that “hillbilly impact” worked well for me. Just put an open ended wrench on the damn bolt and smack it counterclockwise (from the bolts viewpoint). Even though hitting the far end of the wrench would theoretically apply the largest torque impulse to the bolt, I find that there’s too much “slop” out there to really get good torque transfer. I hold the wrench at the end and smack it right around the center. My bolts came loose after about 2 - 3 good smacks with a ball peen hammer.

Much more fun to come, including…

- Clean calipers, brackets, bolts…anything else you removed (optional)

- Clean and re-lube caliper slide pins (optional)

- Paint calipers and top hats of new rotors (optional)

- Install rotors, caliper brackets, calipers, and brake lines (easiest in that order)

- Bench bleed master cylinder and install (can pretty much be done at any point up until now)

- Bleed brakes

- Wipe all brake line fittings down to clean them. Pump the brakes. check for leaks visually and/or using a paper towel.

- Test drive for safety

- Bed brakes according to pad manufacturer’s specs.

Have a good weekend…

eris